In the fast-evolving world of mechanical engineering, automation and smart manufacturing are leading a powerful transformation. From production lines to precision design, industries are adopting smart technologies that not only enhance efficiency but also ensure accuracy, safety, and sustainability. Let’s explore how automation is reshaping mechanical engineering and why it’s the future of manufacturing.

1. What Is Smart Manufacturing?

Smart manufacturing refers to the use of advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), robotics, and data analytics in manufacturing processes. These technologies connect machines, systems, and humans in real-time, enabling data-driven decisions and reducing human error.

For mechanical engineering, this means faster production, improved precision, and reduced waste—all while maintaining consistent quality.

2. The Role of Automation in Modern Mechanical Engineering

Automation plays a vital role in transforming traditional mechanical processes into efficient, digital-driven systems. Whether it’s robotic arms in assembly lines or AI-powered design tools, automation enables engineers to achieve high-quality output in less time.

Key areas where automation is making an impact:

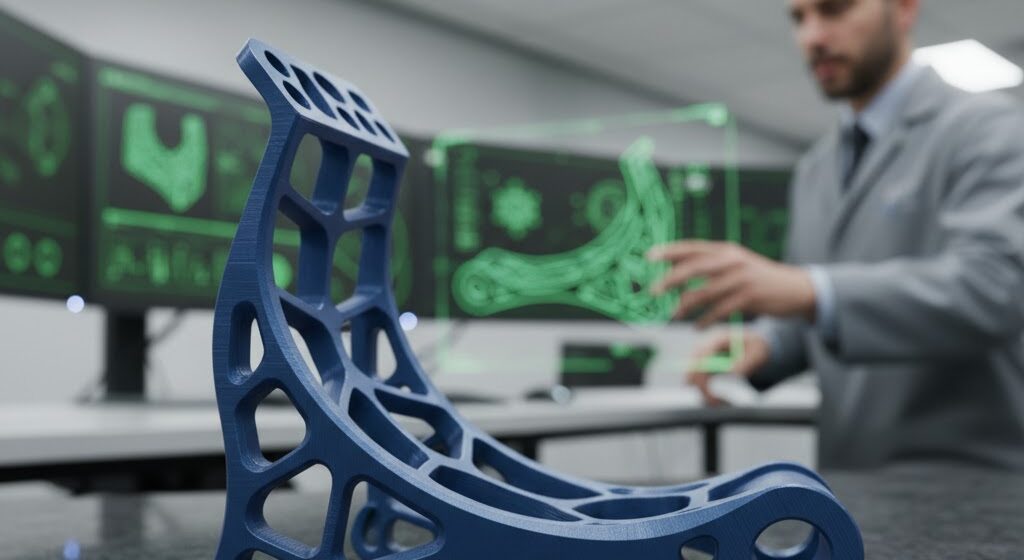

- Design and Prototyping: CAD and CAM systems with AI integration help in quick design adjustments and prototype testing.

- Production Efficiency: Automated systems ensure 24/7 operation with minimal downtime.

- Quality Control: Smart sensors and machine learning algorithms detect defects in real time.

- Maintenance: Predictive maintenance powered by IoT reduces breakdowns and equipment failures.

3. Benefits of Smart Manufacturing

The integration of automation in mechanical engineering provides several benefits, including:

- Higher Productivity: Machines can work continuously, increasing production rates.

- Precision and Accuracy: Automated systems minimize human errors.

- Reduced Operational Cost: Optimized processes mean lower energy and resource consumption.

- Better Safety: Robots handle high-risk tasks, reducing workplace accidents.

- Data-Driven Decisions: Engineers can analyze real-time data to enhance performance.

4. Smart Manufacturing Technologies Driving the Change

Here are some of the most significant technologies revolutionizing the field:

- Industrial IoT (IIoT): Connects machines and devices for real-time monitoring.

- Robotics & Cobots: Robots that work independently or alongside humans.

- Artificial Intelligence & Machine Learning: Improves process optimization and fault detection.

- 3D Printing (Additive Manufacturing): Enables rapid prototyping and custom part production.

- Cloud Computing & Big Data: Stores and analyzes vast amounts of industrial data.

These technologies are helping industries transition from traditional manufacturing to Industry 4.0 — the era of smart, connected factories.

5. The Future of Mechanical Engineering with Automation

The future of mechanical engineering lies in integration, intelligence, and innovation. Engineers of tomorrow will not only design machines but also develop systems that think, learn, and adapt. Smart manufacturing will create new opportunities for efficiency, customization, and sustainability—making it the foundation of next-generation engineering.

6. How Mech81 Embraces Smart Manufacturing

At Mech81, we believe in the power of innovation. Our approach combines mechanical expertise with cutting-edge automation to deliver precise, efficient, and future-ready solutions. From design to production, every process is driven by smart technology and engineering excellence.

We’re not just keeping up with the change—we’re driving it.

Conclusion

Automation and smart manufacturing are no longer just trends—they’re the future of mechanical engineering. By embracing intelligent systems and connected technologies, industries can achieve greater efficiency, reliability, and sustainability.

Mech81 continues to lead this revolution, shaping a smarter and stronger mechanical future.